Wildan Al Hakim, Arif (2018) RANCANG BANGUN MEKANISME PITCH BLADE CONTROL DAN YAW DRIVE CONTROL TURBIN ANGIN HORISONTAL DIAMETER SUDU 10 M. Undergraduate thesis, undip.

| PDF (KATA PENGANTAR,DAFTAR ISI,ABSTRAK) 2314Kb | |

| PDF (BAB I) 279Kb | |

| PDF (BAB II) 568Kb | |

| PDF (BAB III) Restricted to Repository staff only 1451Kb | ||

| PDF (BAB IV) Restricted to Repository staff only 558Kb | ||

| PDF (BAB V) 86Kb | |

| PDF (LAMPIRAN) 154Kb |

Abstract

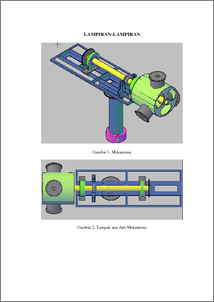

ABSTRAK Salah satu penyebab langkanya sumber daya alam di dunia ini adalah semakin tingginya kebutuhan minyak dan gas (migas). Sementara tingginya migas tidak diimbangi dengan produksi dan sumber energi fosil memiliki kapasitas terbatas. Oleh sebab itu, dibutuhkan sumber daya energi yang terbarukan seperti energi angin, energi matahari, energi panas bumi, energi air, energi biomassa. Dalam kasus ini rancang bangun turbin angin merupakan salah satu solusi untuk mengatasi masalah ini dan kami melanjutkan proyek Tugas Akhir Rancang Bangun Rotor Turbin Angin Horizontal yaitu memfokuskan pada Rancang Bangun Mekanisme Pitch Blade Control dan Yaw Drive Control Turbin Angin Horizontal Diameter Sudu 10 M. Tujuan laporan ini yaitu untuk mengetahui proses pembuatan mekanisme Pitch Blade Control dan Yaw Drive Control berdasarkan perhitungan diameter sudu dan dapat menghasilkan putaran pada generator dengan mempertimbangkan kapasitas maksimal listrik yang dihasilkan generator dan ketersediaan komponenkomponen itu sendiri. Mekanisme Pitch Blade Control dan Yaw Drive Control diuji kekuatannya berdasarkan pengujian analisis kualitatif (kekuatan tuas; kekuatan baut flens; kekuatan roda gigi yaw drive) dan pengujiaan analisis kuantitatif (reliabilitas). Mekanisme Pitch Blade Control dan Yaw Drive Control memenuhi standar sesuai dengan pengujian analisis kualitatif dan pengujian analisis kuantitatif. Oleh karena itu mekanisme tersebut dapat dioperasikan jika mekanisme kelistrikan sudah selesai dan sesuai dengan standar untuk lebih menjaga efisiensi Turbin Angin kapasitas 1 KW (Kilo Watt). Kata Kunci : Pitch Blade Control; Yaw Drive Control; Turbin angin. ABSTRACT One of the causes of the scarcity of natural resources in the world is the increasing demand for oil and gas. While the high level of oil and gas is not balanced with the production and sources of fossil energy has limited capacity. Therefore, renewable energy resources are needed such as wind energy, solar energy, geothermal energy, water energy, biomass energy. In this case the design of a wind turbine is one of the solutions to overcome this problem and we continue the Final Project Project for the Design of a Horizontal Wind Turbine Rotor which focuses on the Design of the Pitch Blade Control Mechanism and Yaw Drive Control Mechanism for Horizontal Wind Turbine Diameter of 10 M. The purpose of this report is to determine the process of making the mechanism of Pitch Blade Control and Yaw Drive Control based on blade diameter and can generate rotation on the generator by considering the maximum capacity of electricity produced by the generator and the availability of the components them selves. The Pitch Blade Control and Yaw Drive Control mechanisms are tested for strength based on qualitative analysis testing (lever strength; flange bolt strength; yaw drive gear strength) and testing of quantitative analysis (reliability). The Pitch Blade Control and Yaw Drive Control mechanisms meet standards in accordance with the testing of qualitative analysis and quantitative analysis testing. Therefore, the mechanism can be operated if the electrical mechanism is completed and in accordance with standards to better maintain the efficiency of a 1 KW (Kilo Watt) Wind Turbine capacity. Keywords: Wind Turbine; Pitch Blade Control; Yaw Drive Control.

| Item Type: | Thesis (Undergraduate) |

|---|---|

| Subjects: | T Technology > TJ Mechanical engineering and machinery |

| Divisions: | Faculty of Engineering > Diploma in Mechanical Engineering Faculty of Engineering > Diploma in Mechanical Engineering |

| ID Code: | 69233 |

| Deposited By: | INVALID USER |

| Deposited On: | 06 Feb 2019 09:34 |

| Last Modified: | 06 Feb 2019 09:34 |

Repository Staff Only: item control page