KUSUMANINGRUM, LINDA (2016) PULPING DAN BLEACHING DARI LIMBAH DAUN JATI KERING DENGAN PENAMBAHAN NATRIUM HIDROKSIDA MENGGUNAKAN ALAT DIGESTER (Pulping and Bleaching from Teak leaves (Tectona grandis) Waste with Addition of Sodium Hydroxide (NaOH) by Using a Digester). Undergraduate thesis, undip.

| PDF (COVER) - Published Version 13Kb | |

| PDF (BAB II) - Published Version 156Kb | |

| PDF (ABSTRAK) - Published Version 20Kb | |

| PDF (BAB I) - Published Version 86Kb | |

| PDF (BAB III) - Published Version 82Kb | |

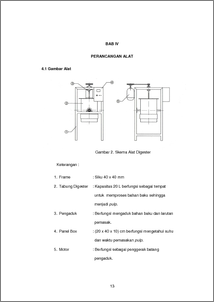

| PDF (BAB IV) - Published Version 132Kb | |

| PDF (BAB V) - Published Version 387Kb | |

| PDF (BAB VI) - Published Version Restricted to Repository staff only 251Kb | ||

| PDF (BAB VII) - Published Version 139Kb | |

| PDF (DAFTAR PUSTAKA) - Published Version 131Kb |

Abstract

Search of alternative materials are needed to reduce raw material on wood pulp only. Waste dried teak leaves contain cellulose which is quite high, so it can be made of alternative materials in the manufacture of paper pulp. This study aims to determine the effect of NaOH concentration and time on the degree of water and cellulose of the teak leaves. Waste dried teak leaves obtained in the village Leyangan , Ungaran .The sewage treatment waste dried teak leaves it can reduce pollution , besides that, can has value over with mixed to pulp . Process pulping used in this study is the process of soda that hydrolyzes dried teak leaf fibers with a solution of sodium hydroxide. To increase the commercial value of the teak leaves pulp, it is necessary to bleaching. One of the bleach can be used is (Ca(ClO)2. The study looked at the effect of pulping time, temperature, the concentration of solvents and bleaching agents on the % yield and % of ISO brightness of paper produced. Range of variables used in this study is the cooking time 80 and 90 minutes with concentrations of 20% NaOH; and temperature with values 90C and 110C The results were analyzed to obtain quality paper % cellulose and % yield. The best pulp result was obtained at cooking time 80 minutes, concentration of NaOH 20%. Keywords: waste dried teak leaves, sodium hydroxide process, pulp, time of pulping

| Item Type: | Thesis (Undergraduate) |

|---|---|

| Subjects: | T Technology > TP Chemical technology |

| Divisions: | Faculty of Engineering > Diploma in Chemical Engineering Faculty of Engineering > Diploma in Chemical Engineering |

| ID Code: | 58312 |

| Deposited By: | INVALID USER |

| Deposited On: | 12 Dec 2017 11:51 |

| Last Modified: | 15 Dec 2017 09:15 |

Repository Staff Only: item control page