Michael, Alvin (2017) Formulasi Flakes Berbasis Labu Kuning dan Kacang Merah dengan Penambahan Natrium Bikarbonat dalam Metode Pengeringan Konvensional (Flakes Formulations Based On Pumpkin And Red Beans With Addition Of Sodium Bicarbonate In Conventional Drying Method). Undergraduate thesis, undip.

| PDF (COVER) - Published Version 27Kb | |

| PDF (ABSTRAK) - Published Version 8Kb | |

| PDF (KATA PENGANTAR) - Published Version 106Kb | |

| PDF (DAFTAR ISI) - Published Version 22Kb | |

| PDF (BAB I) - Published Version 88Kb | |

| PDF (BAB II) - Published Version 496Kb | |

| PDF (BAB III) - Published Version 8Kb | |

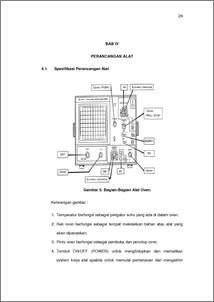

| PDF (BAB IV) - Published Version 181Kb | |

| PDF (BAB V) - Published Version 433Kb | |

| PDF (BAB VI) - Published Version Restricted to Repository staff only 317Kb | ||

| PDF (BAB VII) - Published Version 9Kb | |

| PDF (DAFTAR PUSTAKA) - Published Version 198Kb |

Abstract

Flakes is a food product that belongs to the category of ready-to-eat food cereal or RTE (Ready-to-eat), so it can provide ease in meeting the needs of calories in a relatively short time. The yellow pumpkin is selected as the raw material for flakes, because the mixture of starch and water in the yellow pumpkin is heated, it will expand rapidly and absorb large amounts of water, so it is good to increase the absorption of flakes (Hariyadi 1993). While red beans are selected to improve the nutrients in flakes, specifically proteins and carbohydrates. In the manufacture of flakes using sodium bicarbonate to produce CO2 so as to form cavities within the flakes during roasting, which produce flakes more crisp, less moisture content and has a high absorption. This study analyzed flakes based on moisture content, crispness, absorption and also organoleptically tested, and resulted in the conclusion that the best flakes were with a roasting temperature of 130°C with a roasting time of 25 minutes, because if the heating was increased again, Then there will be the possibility of flakes experiencing non-enzymatic browning reactions and caramelization, resulting in flakes with poor quality. Keyword : Flakes, Drying, Yellow Pumpkin, Red Beans

| Item Type: | Thesis (Undergraduate) |

|---|---|

| Subjects: | T Technology > TP Chemical technology |

| Divisions: | Faculty of Engineering > Diploma in Chemical Engineering Faculty of Engineering > Diploma in Chemical Engineering |

| ID Code: | 58508 |

| Deposited By: | INVALID USER |

| Deposited On: | 20 Dec 2017 13:45 |

| Last Modified: | 20 Dec 2017 13:51 |

Repository Staff Only: item control page