SYAFRUDIN, IRWAN (2016) Optimalisasi Nilai Efektivitas Pada Alat Penukar Panas Jenis Shell and Tube (Optimization of Effectivity Value on Shell and Tube Heat Exchanger). Undergraduate thesis, Undip.

| PDF (COVER) - Published Version 11Kb | |

| PDF (KATA PENGANTAR) - Published Version 86Kb | |

| PDF (ABSTRAK) - Published Version 11Kb | |

| PDF ( BAB I) - Published Version 24Kb | |

| PDF (BAB II) - Published Version 853Kb | |

| PDF (BAB III) - Published Version 83Kb | |

| PDF (BAB IV) - Published Version 162Kb | |

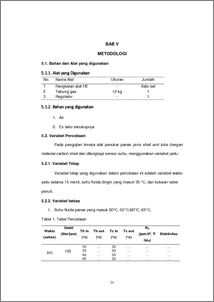

| PDF (BAB V) - Published Version 266Kb | |

| PDF (BAB VI) - Published Version Restricted to Repository staff only 256Kb | ||

| PDF (BAB VII) - Published Version 9Kb | |

| PDF (DAFTAR PUSTAKA) - Published Version 87Kb | |

| PDF (DAFTAR ISI) - Published Version 107Kb |

Abstract

Heat Exchanger is the equipment used to perform the process of heat exchange between two fluids, both liquid (hot or cold) and gas, where this fluid has different temperatures. Some types of heat exchanger are frequently used shell and tube heat exchanger, double pipe heat exchanger and plate heat exchanger. This research aims to determine the rate of heat transfer with temperature variation on the inlet tube and knowing the effective efficiency on heat exchanger shell and tube type. A heat exchanger used in this study is made of carbon steel with specifications include it est specifications of the shell consists of an inner diameter (IDs) 10 in, the number of baffle (N) 7 pieces, the number of passes (ns) 1 pass, and fluid used in the form of hot water; while the specification of the tubes that is outer diameter (ODT) ¾ in, the number of tubes (Nt) 12 pieces, a long tube (L) of 100 cm, number of passes (nt) 2 pass, tube pattern it est triangular pitch, and the fluid being used it est cold water. From these data, it is the heat exchanger is a heat exchanger used for fluid warming or fluid cooling process. The heat exchanger then conducted the testing. Cold water flows into the tube at a steady pace and hot water was flowed into the shell at a steady pace is to change from Tcin and Thin made steady. From the test result showed that if increase fouling factor value then effectivity of heat exchanger will be decrease. Keywords: Shell and Tube Heat Exchanger, Efektiveness, inlet temperatur of the fluid.

| Item Type: | Thesis (Undergraduate) |

|---|---|

| Subjects: | T Technology > TP Chemical technology |

| Divisions: | Faculty of Engineering > Diploma in Chemical Engineering Faculty of Engineering > Diploma in Chemical Engineering |

| ID Code: | 58229 |

| Deposited By: | INVALID USER |

| Deposited On: | 04 Dec 2017 14:18 |

| Last Modified: | 04 Dec 2017 14:18 |

Repository Staff Only: item control page