Subagyo , Ajun (1997) Hubungan penggunaan koagulan PAC dengan kadar A1 tertinggal dalam air PAM. Undergraduate thesis, FMIPA UNDIP.

| PDF Restricted to Repository staff only 1522Kb | ||

| PDF 15Kb | |

| PDF 362Kb | |

| PDF 451Kb | |

| PDF 356Kb | |

| PDF 708Kb | |

| PDF 441Kb | |

| PDF Restricted to Repository staff only 421Kb | ||

| PDF 325Kb | |

| PDF 328Kb | |

| PDF 487Kb |

Abstract

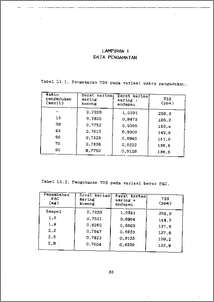

Penjernihan air PAM telab dilakukan dengan menggunakan Poly Aluminium Chlorida (PAC) melalui proses koagulasi. Penggunaan PAC pada penjernihan air PAM dikhawatirkan adanya Al tertinggal dalam air tersebut, sehingga dilakukan penelitian untuk mengetahui hubungan penggunaan PAC dengan kadar Al tertinggal dalam air jernih tersebut. Bahan Baku air PAM digunakan sebagai contoh, ditambah PAC, diaduk, disaring, kemudian ditentukan nilai TSS, COD dan kadar Al dalam air jernih. Ada dua variabel berubah dalam penelitian ini yaitu waktu pengadukan pada proses koagulasi dan berat PAC yang digunakan. Untuk setiap variabel berubah tersebut ditentukan nilai TSS, COD dan kadar Al tertinggal. Hasil penelitian menunjukkan bahwa waktu pengadukan optimum adalah 75 menit dan berat koagulan (PAC) optimum adalah 2,2 mg/L. Nilai TSS pada waktu pemgadukan 75 menit adalah 138,6 ppm, COD 79,52 ppm dan kadar Al 0,8 ppm, sedangkan pada berat PAC optimum TSS 127,6 ppm, COD 75,92 dan kadar Al 1,43 ppm. Dengan meningkatnya berat PAC akan menyebabkan kadar Al tertinggal dalam air semakin miningkat pula. Dari penelitian ini disimpulkan walaupun terjadi peningkatan kadar Al dalam air jernih dengan meningkatnya berat PAC yang digunakan tetapi masih dalam batas normal, begitu pula untuk nilai COD dan TSS. Purification of raw water had been done by the use of Poly Aluminium Chloride (PAC) coagulation process. It was afraid of the remaining of Al, since Al is dangerous. Raw water was used as a sample, added by PAC, stirred, filtered then determinited its TSS, COD, and Al concentration within the water. There were two variable in the research is stirring time in coagulation process and PAC weight used. For variable was determined its TSS, COD, and remaining of Al concentration. The research result shown that optimum stirring time was 75 minutes and optimum coagulant weight was 2,2 ppm TSS value at 75 minutes of stirring was 138,6 ppm, the COD was 79,52 ppm and Al content was 0.8 ppm, where as on optimum PAC weight, TSS was 127,6 ppm, COD was 75,92 ppm and Al content was 1,43 ppm. The greater of PAC weight caused the more concentration of Al remain within the water. The conclusion of this research, although there was a decrease of Al content by the increase of PAC weight used but it was still in the normal limit and also its TSS, COD.

| Item Type: | Thesis (Undergraduate) |

|---|---|

| Subjects: | Q Science > QD Chemistry |

| Divisions: | Faculty of Science and Mathematics > Department of Chemistry |

| ID Code: | 30632 |

| Deposited By: | Mr UPT Perpus 1 |

| Deposited On: | 04 Nov 2011 07:43 |

| Last Modified: | 04 Nov 2011 07:43 |

Repository Staff Only: item control page