Sumedi , Eka (1998) Proses pengerasan Baja Aisi 4140 dengan penyinaran Berkas Laser Co2. Undergraduate thesis, FMIPA UNDIP.

| PDF Restricted to Repository staff only 2157Kb | ||

| PDF 19Kb | |

| PDF 365Kb | |

| PDF 503Kb | |

| PDF 429Kb | |

| PDF 1018Kb | |

| PDF 559Kb | |

| PDF Restricted to Repository staff only 572Kb | ||

| PDF 341Kb | |

| PDF 351Kb | |

| PDF 376Kb |

Abstract

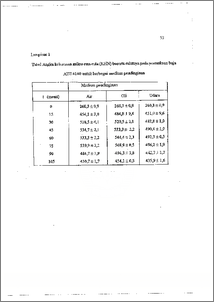

Telah dilakukan proses pengerasan baja AISI 4140 dengan menggunakan laser CO2. Berkas laser difokuskan oleh lenses pemfokus pada permukaan baja tepat pada. titik apinya. Setelah suhu baja naik sampai daerah austenit (sekitat 1000 °C ), kemudian didinginkan secara. mendadak. Pendinginan dilakukan dengan cars membiarkan pada udara terbuka, mencelupkan dalam air, atau oh. Atom katbon dapat terdistribusi secara merata dan akan terjadi penibahan struktur kristal sehingga terjadi proSes pengerasan baja AISI 4140. Dari hasil pengukuran uji kekerasan menunjukkan bahwa untuk proses pendinginan udara , air, dan oli diperoleh kekerasan.maksim.urn (496,2±1,9) x 109 Kgfim2, (539,9± 2,2) x 109 Kge/m2, dan (548,9±0,5) x 109 kgfim2 untuk penyinaran 75 menit. Nilai kekerasan ini naik rata-rata ± 202% dibanding nilai kekerasan awal sebesar ± 260,3 .‘ 109 KgFin2 untuk setiap medium pendinginan. Pengamatan dengan menggunakan SEM (Scanning Electron Mcroscope) menunjukkan perubahan bentuk kristal yang signifikan dengan basil pengerasan yang terjadi sesudah penyinaran berkas laser CO2. Juga diperoleh kedalaman real simum pengaruh berkas laser terhadap kristal sekitar (51,7±0,03) . 10-6 m. Dengan foto SEM teramaii perubalian struktur kristal pada permukaan mencvai kedala.man t20.10.6 rn. A hardening process AISI 4140 steel has been done by using of CO2 laser. The laser beam was focused by lens on the steel surface, of lens precisely on focal length. After the temperatur of the AISI 4140 steel increased up to the aastenit area ( about 10000 C), then suddenly cooled down. The cooling has been done with let then on open air, immerse in the water, or oil. The carbon atomic can be distributed, equally and the structure of cristal would change so it would be the hardening of the AISI 4140 steel. From our results of measurements of the knoop test saw that for the cooling process of air, water, and oil were obtained the maximum hardening (496,2±1,9) x 109 k gf/m2, (539,9±2,2) x 109 kgf1m2, and (548,9-1-0,5) x 109 kgf/m2 for 75 minute of in-adiation The hardening value increased about 202% compared with the initial hardening value. These observatioi Sy SEM (Scanning Electon Microscope) saw that the change of the shape of the cristal significant with the hardening result after irradiation of the CO2 laser. We also obtained the maximum dept of influence of laser beam with respect to cristal about ( 51,7±-0,03 ) x 10-6 in. By the SEM photos, the change of the structure of cristal on the surface pntil depth about 20x10.4 m was observed.

| Item Type: | Thesis (Undergraduate) |

|---|---|

| Subjects: | Q Science > QC Physics |

| Divisions: | Faculty of Science and Mathematics > Department of Physics |

| ID Code: | 30430 |

| Deposited By: | Mr UPT Perpus 1 |

| Deposited On: | 31 Oct 2011 07:48 |

| Last Modified: | 31 Oct 2011 07:48 |

Repository Staff Only: item control page